There are some fundamental rules that need to be applied (these can be found on page 7 of the 2009 edition of the standard): GD&T can add quality and reduce cost at the same time through producibility. Proper application of GD&T will ensure that the part defined on the drawing has the desired form, fit (within limits) and function with the largest possible tolerances. GD&T can more accurately define the dimensional requirements for a part, allowing over 50% more tolerance zone than coordinate (or linear) dimensioning in some cases. The datum reference frame can describe how the part fits or functions. Dimensioning and tolerancing philosophy Īccording to the ASME Y14.5-2009 standard, the purpose of GD&T is to describe the engineering intent of parts and assemblies. In 1956, Parker published Drawings and Dimensions, which became the basic reference in the field. In 1940, Parker published Notes on Design and Inspection of Mass Production Engineering Work, the earliest work on geometric dimensioning and tolerancing. His work increased production of naval weapons by new contractors.

While little is known about Parker's life, it is known that he worked at the Royal Torpedo Factory in Alexandria, West Dunbartonshire, Scotland. The origin of GD&T is credited to Stanley Parker, who developed the concept of "true position".

#Gd&t book download asme y14.5 standarad verification

#Gd&t book download asme y14.5 standarad iso

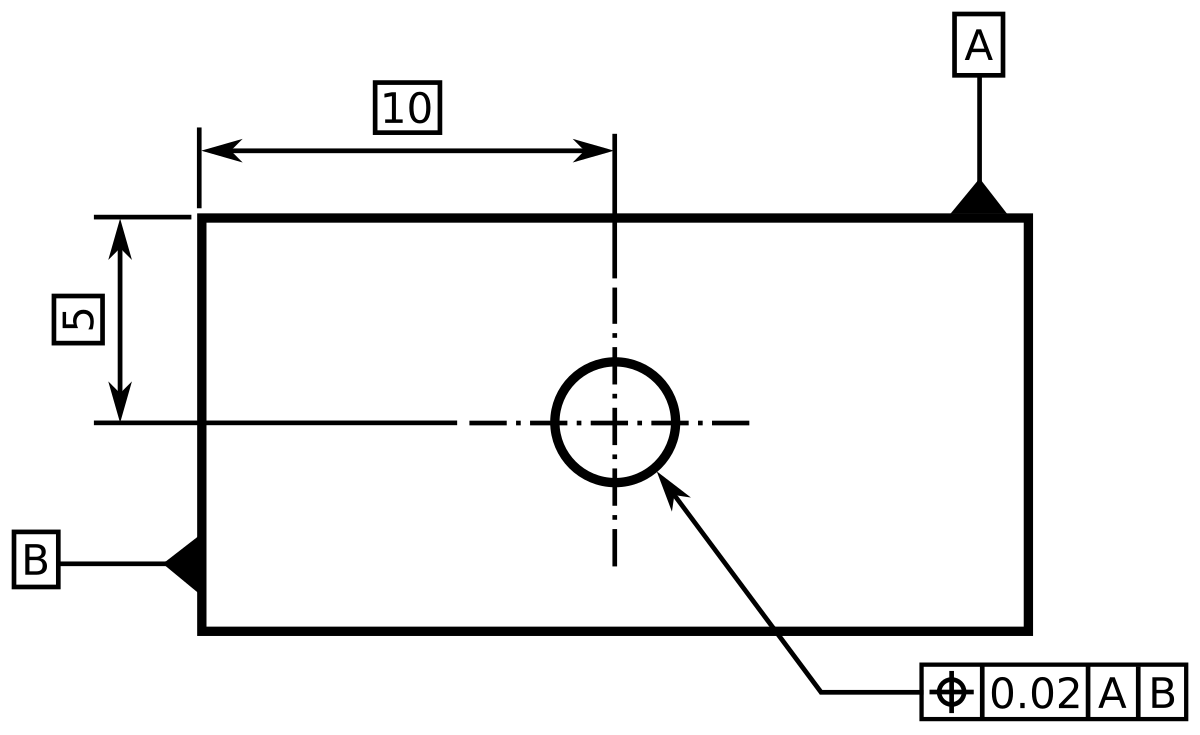

There are separate standards that provide the details for each of the major symbols and topics below (e.g. The ISO standards, in comparison, typically only address a single topic at a time. The Y14.5 standard has the advantage of providing a fairly complete set of standards for GD&T in one document. This article is based on that standard, but other standards, such as those from the International Organization for Standardization (ISO), may vary slightly. One such standard is American Society of Mechanical Engineers (ASME) Y14.5. There are several standards available worldwide that describe the symbols and define the rules used in GD&T. Two examples are linear dimensions and feature control frames using a datum reference (both shown below).

0 kommentar(er)

0 kommentar(er)